SANMAR has held a steel cutting ceremony to mark the start of construction in a major project to provide four of its world-leading electric battery-powered ‘Tugs of the Future’ for Türkiye’s state-owned BOTAŞ Petroleum Pipeline Corporation.

The ceremony took place on October 11th at SANMAR’s purpose-built state-of-the-art Altinova Shipyard in the heart of the Turkish maritime sector.

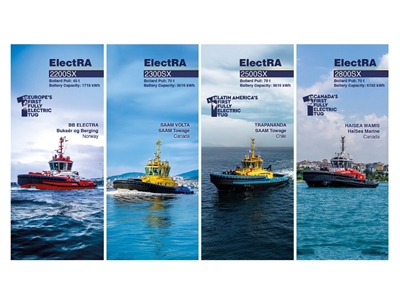

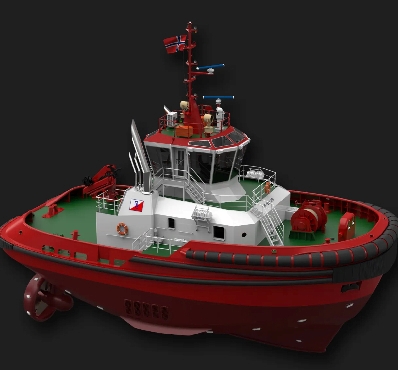

BOTAŞ has ordered four ground-breaking emissions-free tugs based on the exclusive-to-SANMAR ElectRA 2500-SX design from renowned Canadian naval architects Robert Allan Ltd. Known now as simply hull numbers 379, 380, 381 and 382, when completed each tug be capable of achieving an impressive 70 tonnes of bollard pull ahead, a speed of approximately 12 knots and have accommodation for a crew of up to eight.

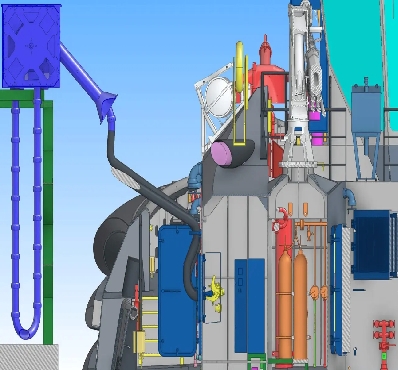

Each boasting battery banks producing 5,085 kWh, these formidable tugs will also include backup diesel gensets for fire-fighting and range-extended endurance. Their tank capacities will include 54m3 of fuel oil and 18m3 of fresh water.

The steel-cutting ceremony was attended by Cem Seven, Vice Chairman of Sanmar Shipyards, and other SANMAR management and employees. Guests included Erdinç Deli, BOTAŞ LNG Operations Manager, along with other BOTAŞ managers and employees; Deniz Kaya, Yalova Harbour Master, the Board Members of the Turkish tug operator YALPAŞ, other Turkish maritime sector managers, and SANMAR stakeholders.

Cem Seven, Vice Chairman of the Board of Sanmar Shipyards and Chairman of the Board of Ship Yacht and Services Exporters Association, said the following in his speech at the ceremony: “The world is going through a significant transformation process with the transition to the use of environmentally friendly fuels. In line with IMO’s goals, the sector is expected to reach net zero greenhouse gas emissions by 2050. In this context, the importance of alternative fuels in maritime is increasing. It is seen that the most suitable solution for tugboats and marine vehicles to be used in port services is electric drive systems. We wish the 4 ElectRA 2500-SX tugboats with 70 tons of bollard pull to be beneficial for BOTAŞ, and we thank them for their trust in Sanmar Shipyards and their environmentally friendly approach.”

Erdinç Deli, LNG Operations Manager of BOTAŞ, said: "First of all, on behalf of BOTAŞ family, we would like to thank to the valued executives and employees of our contractor, SANMAR, for their kind invitation to the steel cutting ceremony for our project to supply 4 Electric Tugboats.

We are jointly starting the manufacturing process of 4 Electric Tugboats, which will be used in the maneuvers of LNG carriers that will berth at BOTAŞ Marmara Ereğlisi LNG Terminal and BOTAŞ Saros FSRU Terminals, which have strategic importance for ensuring our country's energy security.

As you know, the maritime sector is one of the sectors which is severely affected by global warming and climate change. Hence, transitioning to environmentally friendly technologies is of critical importance for both the future of our sector and the future of our world. Moreover, our cooperation with Sanmar, which is in line with the "Fossil Fuel-Free Maritime Industry" targets included in our National Energy Efficiency Action Plan, will be a significant milestone in this transition.

I believe that this journey we are starting here today will open a new chapter in the maritime sector and contribute to providing a cleaner world for future generations. I thank you all and wish success in our project."

Erdinç Deli (LNG Operations Manager) and Bülent Altun (Maritime Affairs Manager) performed the first steel cutting by means of Sanmar’s technologically-advanced computer numerical control CNC cutting machine, and the ceremony ended by Cem Seven presenting a commemorative plaque to Erdinç Deli.

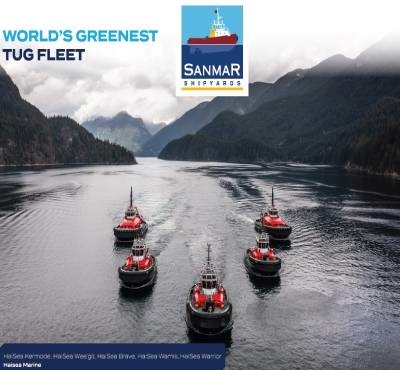

Sanmar’s game-changing ElectRA Series tugboats are the result of the tugboat builder’s ongoing collaboration with Robert Allan Ltd and Corvus Energy to build low and no-emission tugs utilising alternative fuels and innovative technological advances to protect the environment and build a sustainable tug and towing industry.

,672_big.jpg)

,677_big.png)

,685_big.jpg)

,690_big.jpg)

,374_big.png)

,78_big.jpg)

,86_big.jpg)

,95_big.jpg)

,96_big.jpg)

,97_big.jpg)

,101_big.jpg)

,103_big.jpg)

,113_big.jpg)

,114_big.jpg)

,116_big.jpg)

,120_big.jpg)

,122_big.jpg)

,131_big.jpg)